Investigating a New Material: Basalt

I’m finally getting around to documenting some of the work I did at Red Lodge Clay Center with a material I had very little experience with the time, basalt. I was lucky to happen upon Pioneer Valley Basalt available in two versions, Microfine Basalt and BrixBlend Basalt. The microfine version was great for glazes, and the material came with a detailed chemical analysis.

We’re not always so lucky, though, to have chemical analyses for our ceramic materials, especially local and non-traditional ones. In these situations, I usually go about a number of investigations to narrow down its chemistry and determine how it best works in glazes or clay bodies.

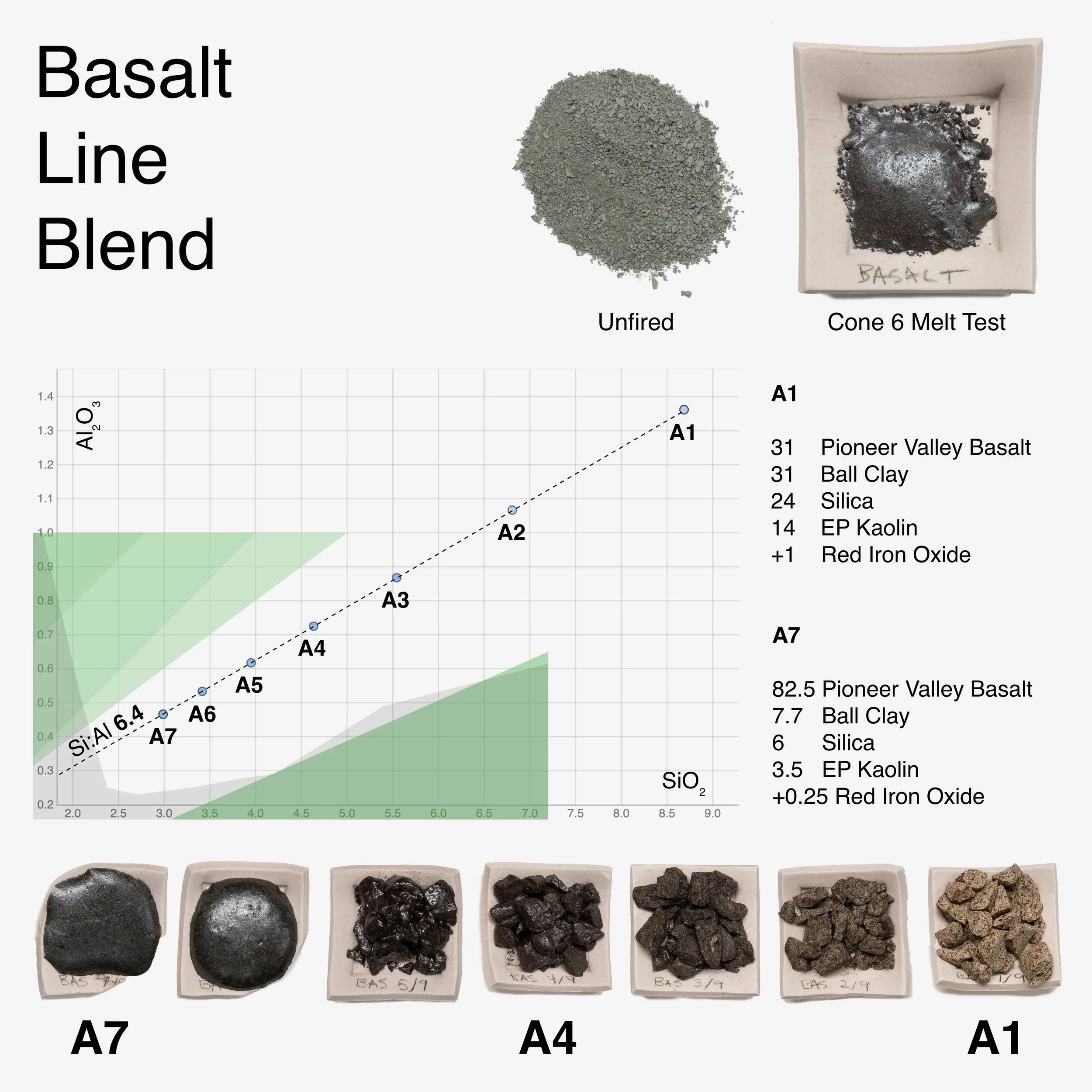

Step 1: Put it in the kiln

A revealing and simple test is to simply put the material in the kiln and see what happens, aka a melt test. On the left is the raw material (microfine basalt), and on the right is after the material is fired to Oxidation Cone 6 in an electric kiln.

Step 2: Simple Line Blends

For information about blend testing, please see “Blend Testing” in Glazy Help.

The two recipes in my “simple” line blend might not look simple, but they’re just mixtures of basalt with one of my cone 6 stoneware body recipes: A1 is mostly cone 6 stoneware, while A7 is mostly basalt. You could do the same test with using any dried & crushed clay body and mixing in a line blend with a material, e.g. 100% basalt, 80/20% basalt/clay, 60/40% basalt/clay, 40/60% basalt/clay, 20/80% basalt/clay, and 100% clay.

Types of line blends I often do:

Unknown material + clay body (as in this example). For example, the “left” test would be 100% basalt, while the “right” test could be 100% clay body. Your blends could be in 10% increments, e.g. 100% basalt, 90% basalt + 10% clay body, 80% basalt + 20% clay body, etc.

Unknown material + flux (e.g. whiting, dolomite, boron frit, etc.). Similar to the previous test, the “left” test could be 100% basalt while the “right” test could be 80% basalt + 20% whiting. A line blend could then be: 100% basalt, 95% basalt/5% whiting, 90% basalt/10% whiting, 85% basalt/15% whiting, and 80% basalt/20% whiting.

Example of mixing basalt with a stoneware clay body. Cone 6 oxidation firing.

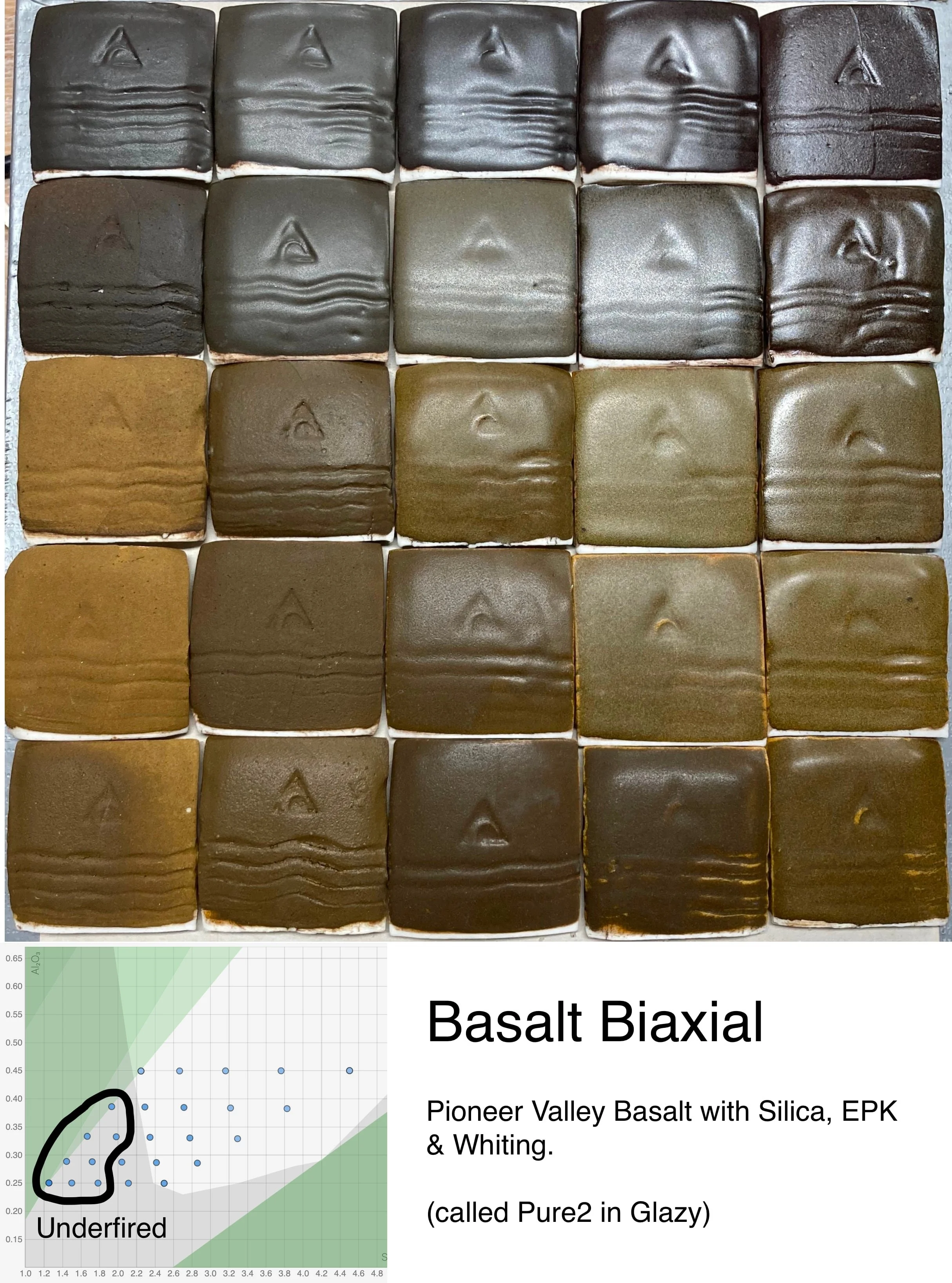

Step 3: More Complex Biaxials

For handy blending guides, please see Glazy Help.

Melt tests and line blends are great for getting a general idea of the unknown material you are dealing with. Biaxials allow you to narrow down even further. By using information gained from simpler tests, one can design biaxial tests that are more informed and purposeful.

Because I had access to the chemical analysis of my basalt material, in the biaxial tests below I was able to “design” or place the corner glazes of the biaxial (A1, A4, D1, D4) in exact locations: The columns lie along fixed Si:Al ratios that roughly correspond to Stull Regions, while the rows lie along fixed Al2O3 levels.

Even if you don’t have a chemical analysis for the material you are testing, you can still design a biaxial with varying silica and alumina by adding kaolin and silica/quartz. As an example, if the bottom corner D1 is pure basalt (or basalt + flux), the top-left A1 could then be D1 + 15 kaolin, top-right A4 could be D1 + 15 kaolin and 15 silica, and bottom-right would be D1 + 15 silica.

Example of a biaxial with columns aligned with fixed Si:Al ratios and rows with fixed Al2O3 levels.

Another example of blending four corner glazes in a biaxial with basalt, silica, whiting, and kaolin. Here, the columns still correspond to fixed Si:Al ratios, but the rows are “diagonal” with varying levels of alumina.

Curated basalt glazes resulting from various blend tests.

Some examples of recipes that came out of the above Basalt “Pure” Biaxial:

Target & Solve Tutorial Video

Sometimes we come across recipes that contain materials we don't have in our studio. But this isn't usually a problem, because we can use material substitution. In this tutorial, I'll show you how Glazy's Target & Solve feature can be used to automatically substitute materials in a recipe.